We offer a comprehensive range of services for implant manufacturers

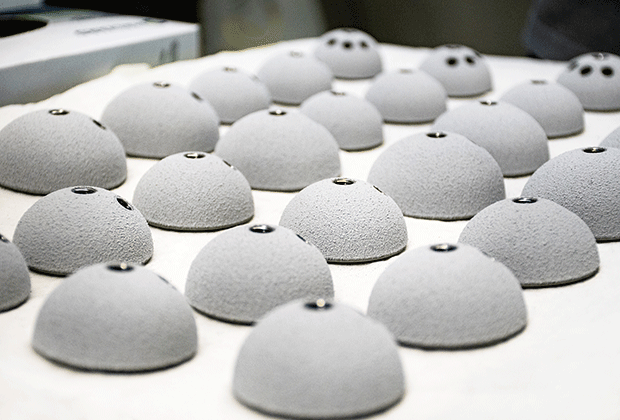

Plasma Coating

Process:

The coater sprays the coating powder and heats it to a temperature above its melting point with the plasma torch. This allows the powder to be fixed to the surface.

A robotic arm allows the machine to move as close as possible to the parts to be coated, achieving high coating precision.

The coating can be done in one or more layers with titanium and/or hydroxyapatite powders.

During plasma coating, we take care to maintain the physical properties of the product to avoid premature failure of the medical devices.

The coating of your products is carried out in a category ISO 6 clean room. As the product is disinfected before coating, the washing process is more efficient as microbial adherence is limited.

Furthermore, the coating is not altered by the washing cycle, which can be abrasive for the product.

The coating thickness is regularly checked in our in-house laboratory to ensure the repeatability of the coating process.

Each batch of coating powder is analysed with chemical and mechanical tests.

Translated with www.DeepL.com/Translator (free version)

Partnership

More than 30 years of experience in plant engineering and spraying technology enable Medicoat to partner in wide areas of medical technology. In addition to the mechanical production and coating of implants, we also offer our customers laser marking and clean room packaging of their orthopaedic products.

Contact us