Substrates

Metal

Polymer

Ceramic

Various material combinations are possible

Through customized coating equipment, spray powders and know-how of the entire coating process, Medicoat is able to coat a wide variety of substrate materials and realizes new implant properties through various material combinations.

Contact us

Metals and Alloys

Titanium, Titanium alloys, Cobalt Chromium alloys,….

Polymers: PEEK and PEKK implants combined with our vacuum plasma spraying technology.

Through further developments of vacuum plasma spraying (VPS), implants based on PEEK, CFR-PEEK, PEKK and long-fiber-reinforced materials are coated with rough titanium and/or hydroxyapatite coatings. Thus spinal implants (cages), pedicle screws and also cranial plates made from PEEK with improved osseointegration properties are realized.

Based on targeted part manipulation, Medicoat can also offer coatings on PEEK imlants with complex geometires and open structures, which means osseointegration is not only limited to bone contact surfaces but also within the structure of implants. This supports the ingrowth of bone thoughout the entire implant.

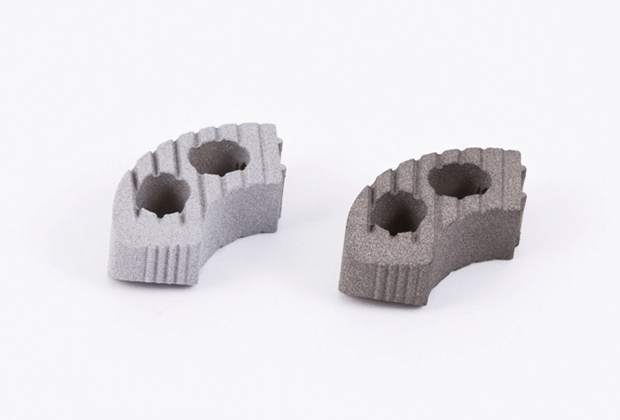

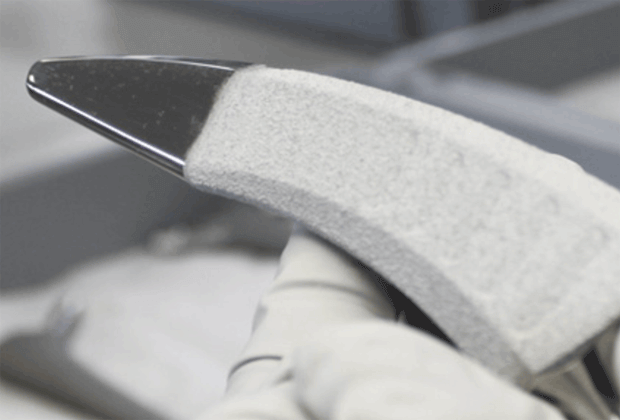

Ceramic Implants

Last a lifetime

Implants for increasingly younger patients require the development of artficial joints with improved long-term properties.

This is where ceramic implants come into play. They are characterized by abrasion-resistent bearing properties. However, the disadvantage of these material is that bone cells can not anchor derictly on the surface. This is where Medicoat steps in - we modified the VPS coating process in such a way that rough, open-pored and bioactive titanium and hydroxyapatie coatings with high adhesion and shear strength can be deposited on ceramics.

Various substrates? – No Problem, we realize our coatings on a wide range of different substrate materials.