Coating Powder Overview

Broad range of coating powders for diverse applications

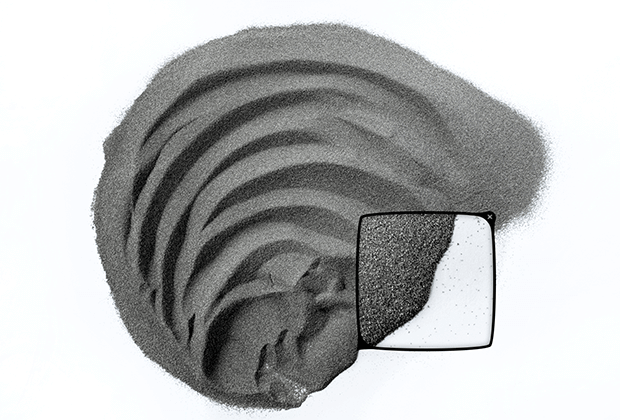

Production of Hydroxyapatite powders

Our Medipure® hydroxyapatite powder is sintered and crushed in a proprietary process. This makes sure that this powder has the required phase composition and offers an excellent flowability and feed capacity. Using classifying processes, we can adjust the particle size distribution in many ways. All powders meet the quality standards ASTM 1185, 1088 and ISO 13779.

Processing Medipure® titanium powders

Our high-purity Medipure® type titanium powders are synthesized by reduction to the metal, based on titanium dioxide. They are customized to the required particle size distribution using our classification plant and meet all requirements of ISO 13485.

Powder feeding

To achieve a high process and coating quality and to implement a very good reproducibility, a highly constant feed rate of the powder is indispensable. Powders need to be fed and transported easily and continuously with a feed gas stream. Medicoat designs and manufactures the necessary powder feed systems and customizes them for the individual coating applications, if needed.

Process development

We support our customers in the development and optimization of coating processes. In this way we provide you with the ability to produce coatings with defined and reproducible properties by using highly economic processes.

Research and development

We adjust the properties of powders within the physical boundaries to make new applications or coating concepts possible. Deep knowledge and long-standing experience with the interaction of coating machines, powders and processes enables our systemic approach. Only in this way we can tap all the potential of such a complex coating system and find new solutions to coming challenges.

Broad range of coating powders for diverse applications

Production of Hydroxyapatite powders

Our Medipure® hydroxyapatite powder is sintered and crushed in a proprietary process. This makes sure that this powder has the required phase composition and offers an excellent flowability and feed capacity. Using classifying processes, we can adjust the particle size distribution in many ways. All powders meet the quality standards ASTM 1185, 1088 and ISO 13779.

Processing Medipure® titanium powders

Our high-purity Medipure® type titanium powders are synthesized by reduction to the metal, based on titanium dioxide. They are customized to the required particle size distribution using our classification plant and meet all requirements of ISO 13485.

Powder feeding

To achieve a high process and coating quality and to implement a very good reproducibility, a highly constant feed rate of the powder is indispensable. Powders need to be fed and transported easily and continuously with a feed gas stream. Medicoat designs and manufactures the necessary powder feed systems and customizes them for the individual coating applications, if needed.

Process development

We support our customers in the development and optimization of coating processes. In this way we provide you with the ability to produce coatings with defined and reproducible properties by using highly economic processes.

Research and development

We adjust the properties of powders within the physical boundaries to make new applications or coating concepts possible. Deep knowledge and long-standing experience with the interaction of coating machines, powders and processes enables our systemic approach. Only in this way we can tap all the potential of such a complex coating system and find new solutions to coming challenges.