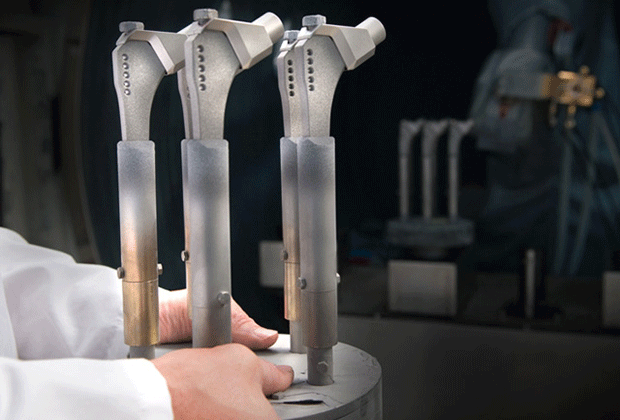

Medicoat is specialist for thermal spraying focussing plasma spraying. We coat implants and devices for renowned companies.

We offer implant manufactures e.g. specifically optimised Titanium (Ti) and Hydroxyapatite (HA) coatings that meet all ISO standards and ASM requirements. The coating production is performed under the strict quality standards of ISO 13485 and/or FDA using our own developed and manufactured coating equipment.

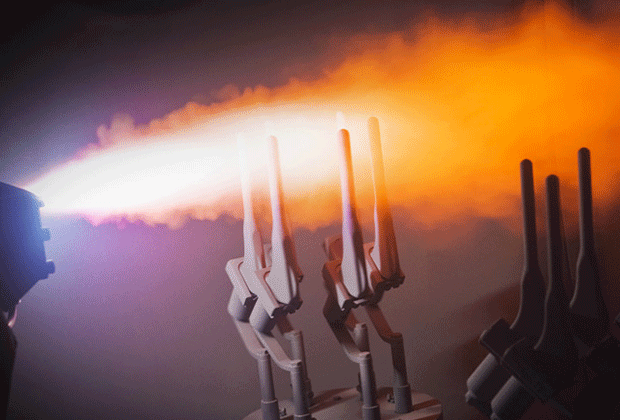

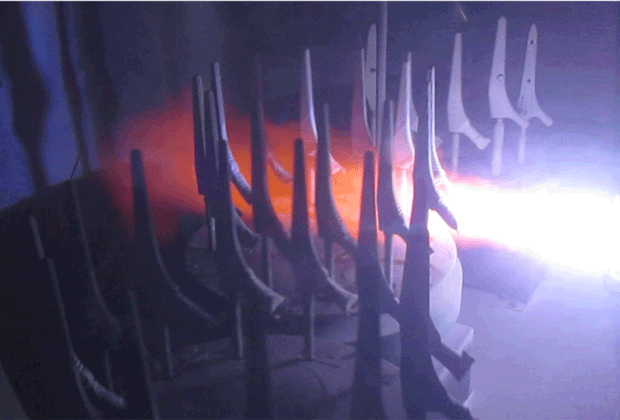

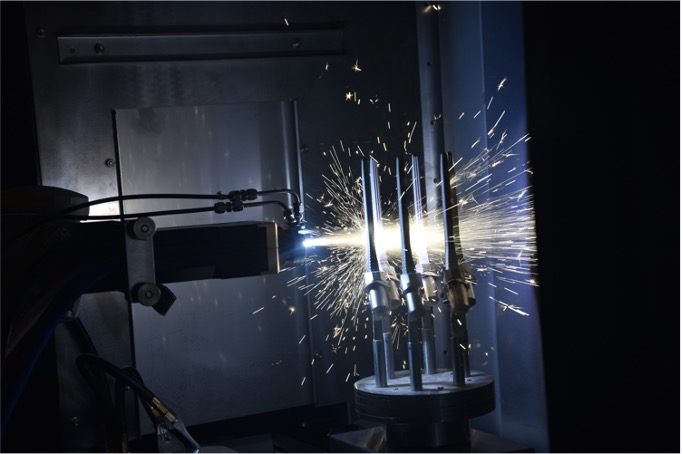

Vacuum Plasma Spraying VPS

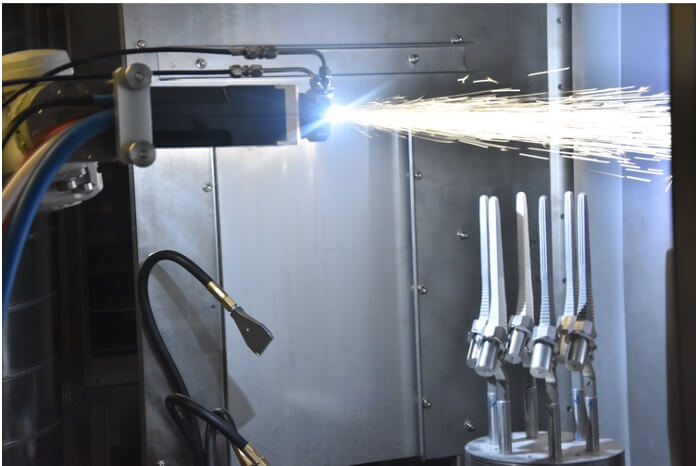

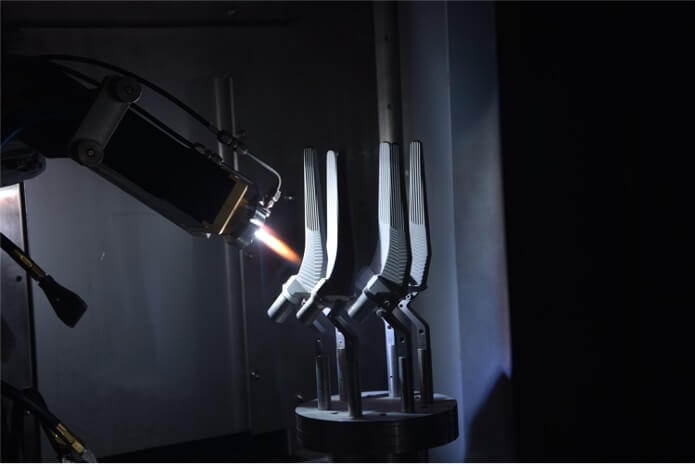

Atmospheric Plasma Spraying APS

Titanium and Hydroxylapatite Coatings

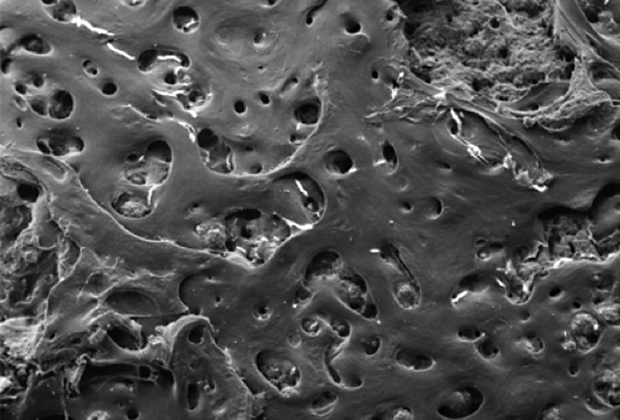

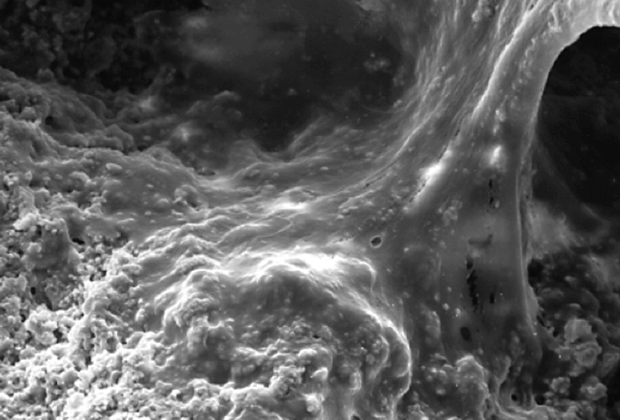

Titanium and Hydroxyapatite coatings – the perfect surface for osseous integration of implants.

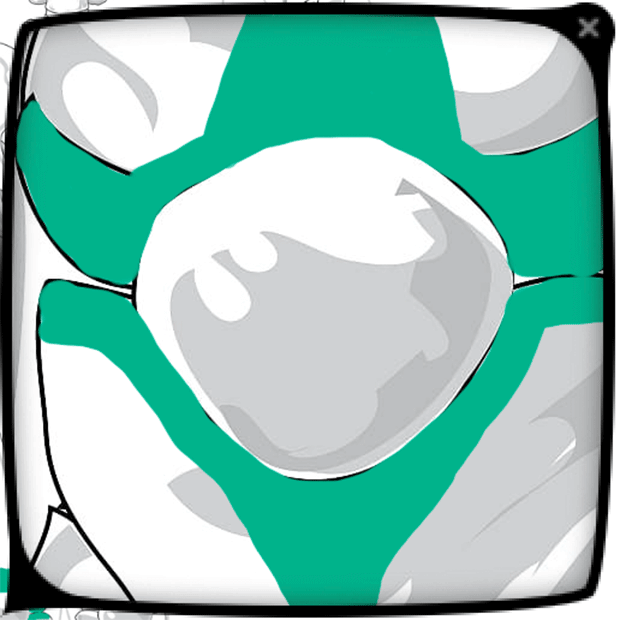

Bone cells connected with coated implant surface

Specified coatings

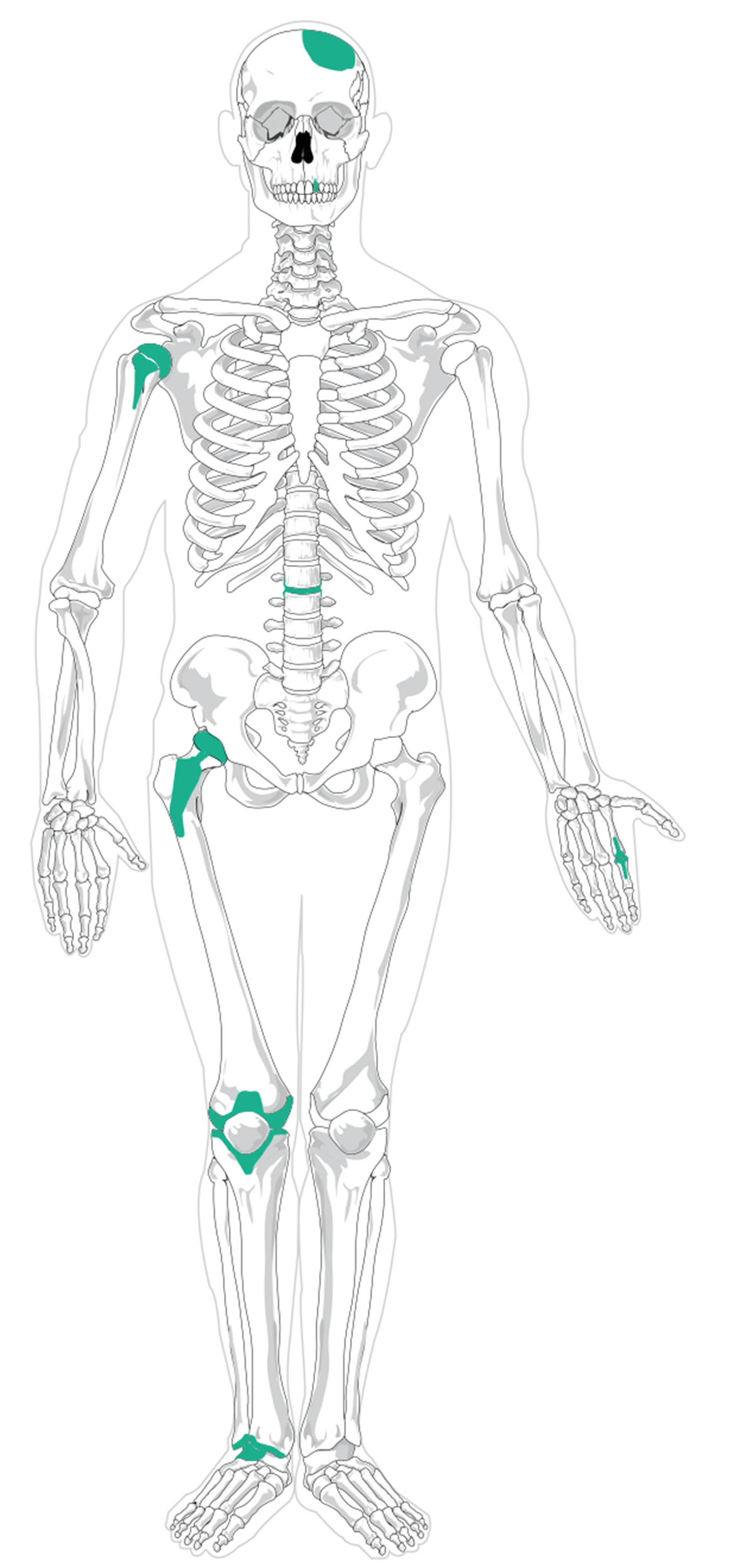

From the top of the skull to the small screw of a denture, we can offer specified Ti and HA coatings

Areas of application for Medicoat Coatings

What it's all about:

The successful use of Medicoat Coating Systems over decades combined with continuous further development of process and system technology has led to an expansion of the areas of application. Whereas in the past mainly classic hip implants were coated, today Medicoat coatings are used on a wide variety of implants and materials.

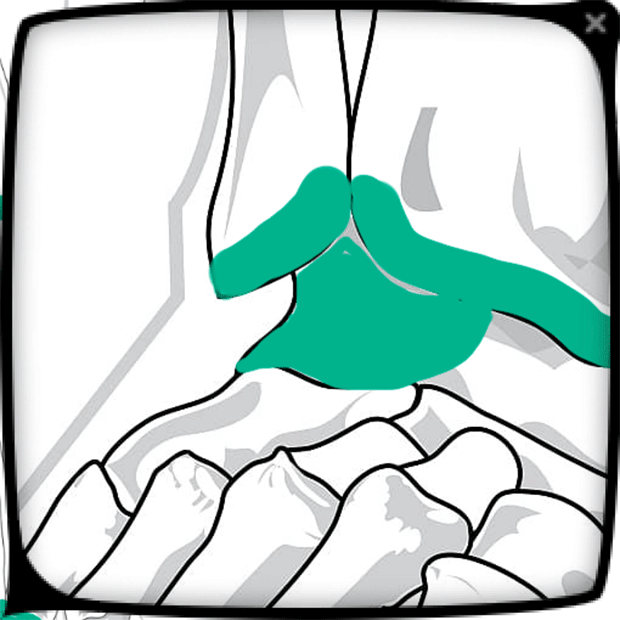

Ankle Joint

Hip Joint

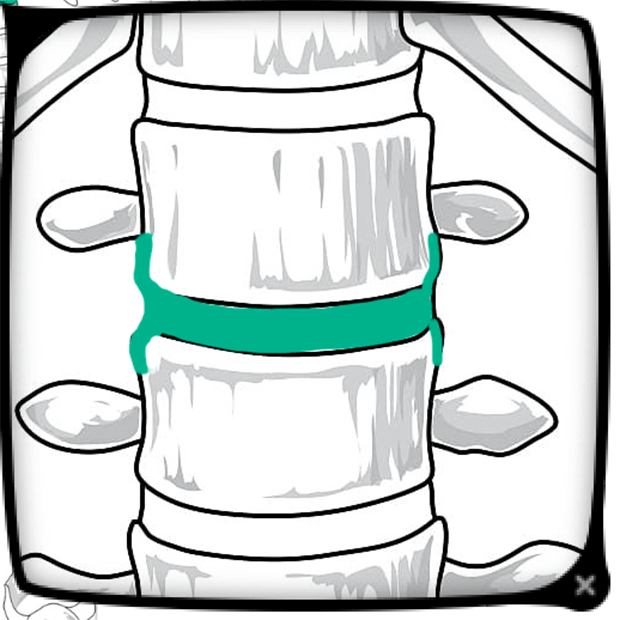

Spine

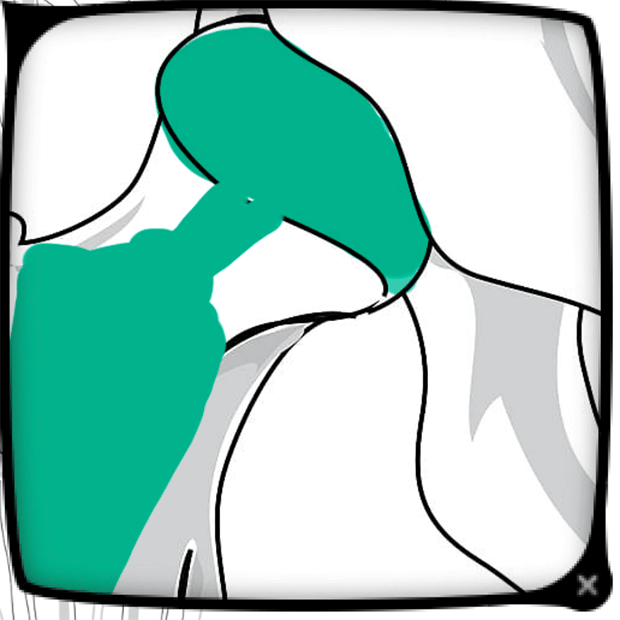

Shoulder Joint

Finger Joint

Skullcap

Medicoat layers are also used in veterinary medicine.