Coating systems for Titanium and Hydroxyapatite

With Titanium

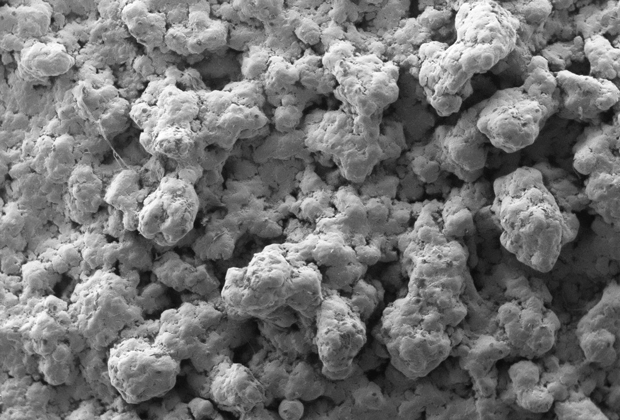

Titanium (Ti) is widely used in the field of medical technology due to its mechanical strength, corrosion resistance and biocompatibility. On implants, a titanium coating with a specific surface structure creates perfect conditions for bone cells ingrowth. The coating forms pre-condition for a permanent bonding between implants and bone cells. It subsequently realizes the stable anchoring of the implant in the bone.

Medicoat realizes by different thermal spray technologies different titanium coating structures depending on the application and substrate material. For example, vacuum plasma spraying (VPS) can be used to deposite thick and pure titanium with an oxygen content < 0.5 % and an open-pored structure. Also thin titanium coatings on already macrostructured substrate surfaces («groove structure») or small implants are applied.

Hydroxyapatite (HA) is natural element of the bone. It`s bioactive property stimulates and supports the osseointegration of the implant. The implant is covered by bioidentical cloak of invisibility and the ingrowth of the HA-coated implant is identical to the healing process of a bone fracture.

Depending on the requirements, thick and open-pored Ti coatings, for example, are covered with a thin HA coating in order not to close the surface roughness. In contrast, thick HA coating are also used on thin Ti coating. In this case, the titanium coating functions primarily as a bonding layer which increases the adhesion of the HA coaing on the substrate.

Depending on the application, the implant geometry and the substrate material, a variety of coating systems are realised.

Pure Titanium Coatings

Thin

Thick

Coating combination of Titanium and Hydroxyapatite

Thin Titanium + Thick Hydroxyapatit

Thick Titanium + Thin Hydroxyapatit