Hydroxyapatite for Thermal Spray Technology

What is Hydroxyapatite?

Hydroxyapatite is the major component, and an essential ingredient, of normal bone and teeth. The osseointegration of an implant can be accelerated by a hydroxyapatite coating. The ingrowth process time of the HA-coated prosthesis is identical to the healing process of a bone fracture.

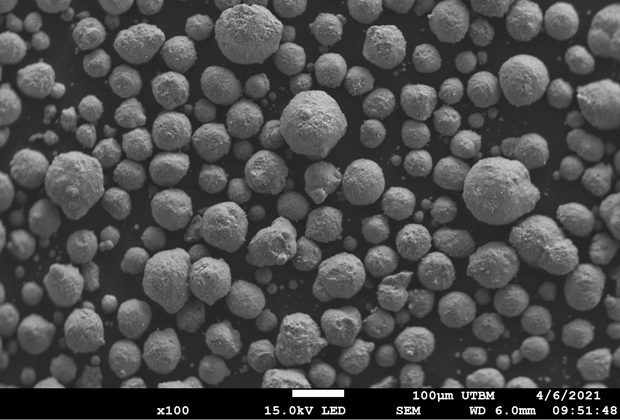

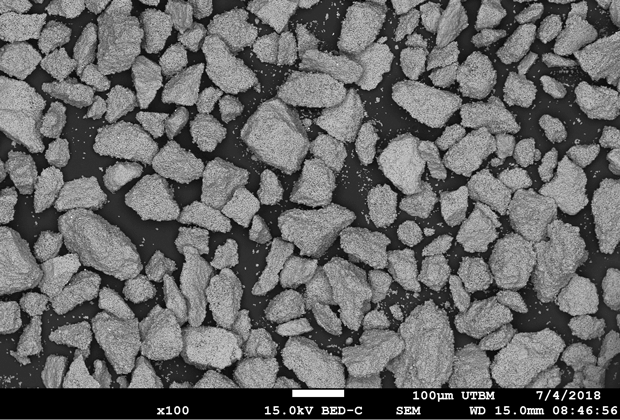

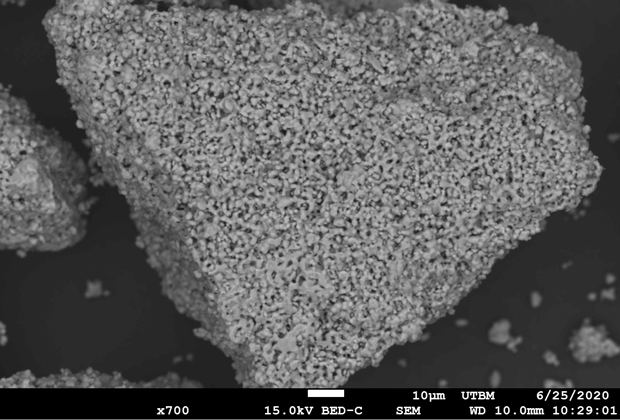

Medicoat offers a wide range of sintered and crushed hydroxyapatite powders adapted for thermal spray technology with irregular grains as well as agglomerated powders with spherical grains.

Application

Atmospheric Plasma Spraying (APS), Vacuum Plasma Spraying (VPS), Suspension Plasma Spraying (SPS)

Characteristics

- Conform standards: ASTM F1185 and ISO 13779

- Grains morphology: irregular or spherical shape; dense or porous

- Good flowbility

- Particles size: <15µm ; 5-25µm ; 15-25µm; 15-45µm ; 25-63µm ; 25-75µm ; 15-125µm ; 25-125µm ; 32-125µm ; 32-106µm ; 45-125µm ; 45-150µm ;

- Hard particles adapted for high bond strength coatings: σ > 20MPa

- White coatings

Advantages

- Excellent mechanical properties of coatings

- Manufacture of homogeneous lots are available until 600kg

Hydroxyapatite powders are manufactured on site in France so Medicoat can customize powders characteristics such as particle size distribution, density, etc…, to meet your coating requirements.