Quality tested on site in our own laboratory

Metallography

Coating thickness & Porosity

Adhesion

Tensile and Shear test

Abrasion

Roughness

Optical Scanner (GOM)

XRD

_

Customized

Laboratory for Coating and Powder Analysis

Insights into the test methods

Metallography

- Coating thickness according to ASTM F1854

- Porosity according to ASTM E2109

- Mean Void Intercept Length - MVIL accorting to ASTM 1854

- Tissue Interface Gradients - TIH according to ASTM 1854

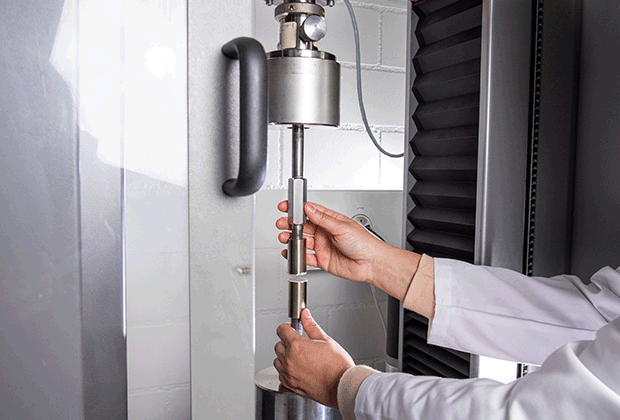

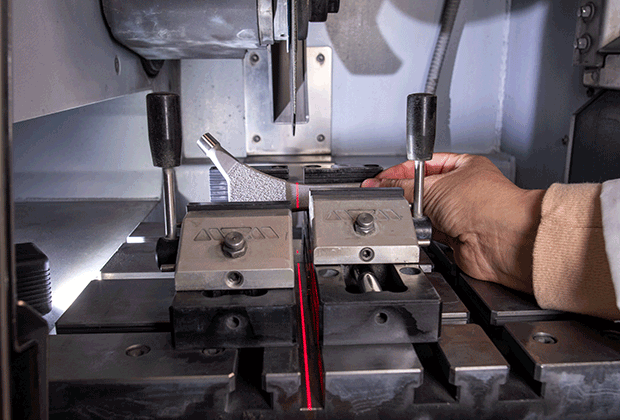

Adhesion

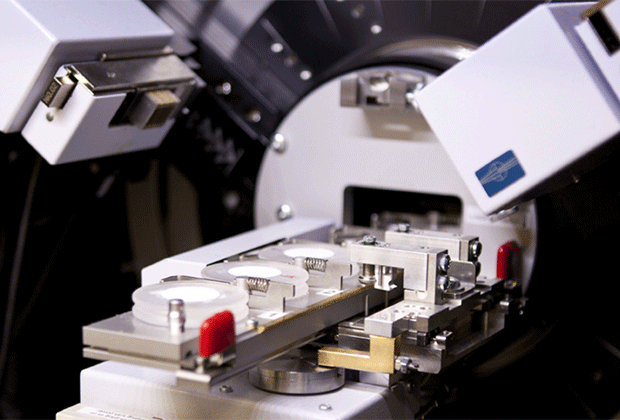

Tensile and Shear test

Coating of test samples, preparation, performance and determination of:

- Tensile test according to

ASTM 1147 and ISO 13779-4 - Shear test according to

ASTM F 1044 - Shear fatigue testing according to ASTM F 1160

Tensile force up to 50 kN

The tensile adhesion test is used to determine the adhesive tensile and shear strength of thermally sprayed coatings and substrate material (especially in medical technology) under tensile or shear load.

Using effective and flexible software, we perform tests according to existing standards and customer requirements and provide the associated test reports.

(We develop specific bonding fixtures to perform tests suitable to your test sample and specified test requirements).

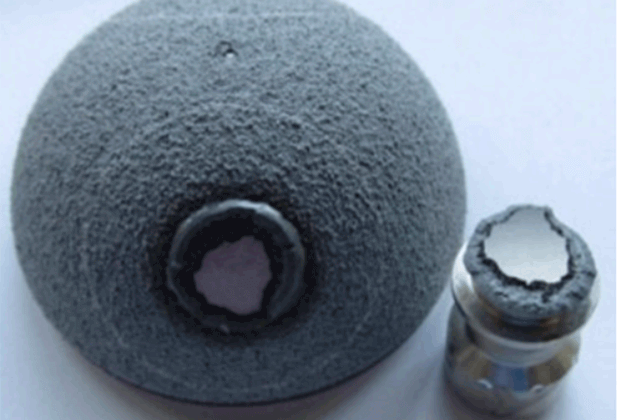

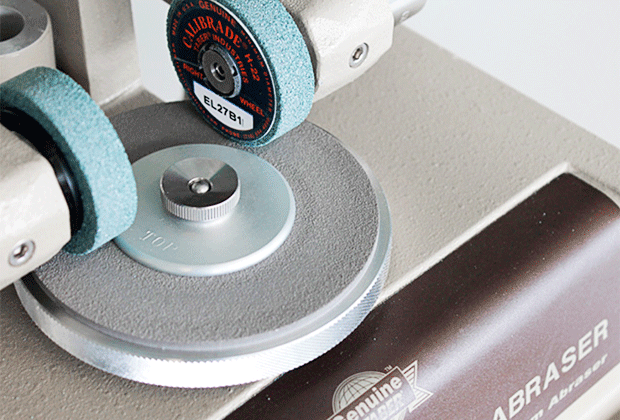

Abrasion

Taber tests

Coating of test plates, performance and determination of

- Abrasion resistance (Taber Abraser) of metallic spray coatings according to Porosity according to ASTM F 1978

This test method qualifies the abrasion resistance of metallic coatings, produced by thermal spray processes on flat surfaces.

The specimens to be tested, placed on the turntable of the abrasion device, are subjected to the abrasion effect by two grinding wheels with fixed pressure.

Abrasion resistance is checked for all possible angles with respect to the specimen and measured with an accuracy of up to 0.0001g

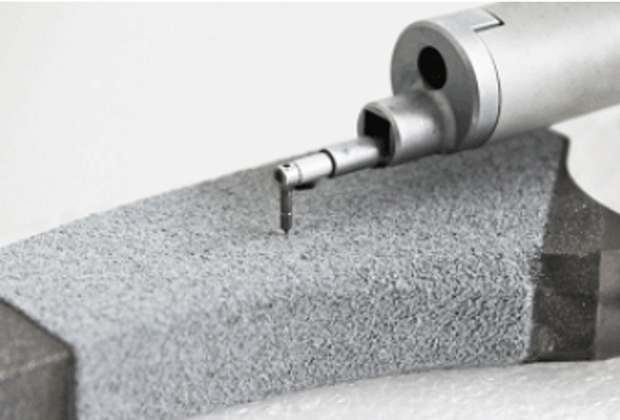

Roughness

- Roughness measurement according to ISO 4287/4288 und ISO 3274

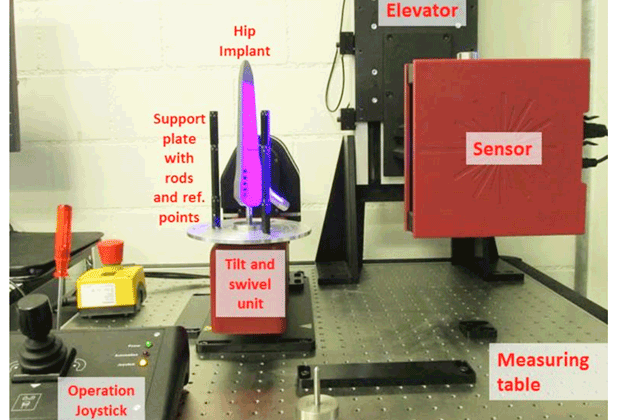

Optical Scanner (GOM)

XRD

Röntgendiffraktion

Performance and analysis of:

• Crystallinity of calcium phosphate spray powders and coatings according to ISO 13779

Powder Laboratory

For new coating concepts and applications, the properties of powders are specifically adjusted within physical limits in our powder laboratory.