Overview of coating systems and coating processes

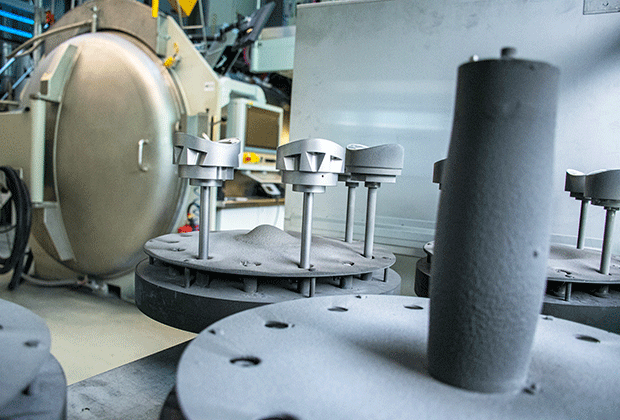

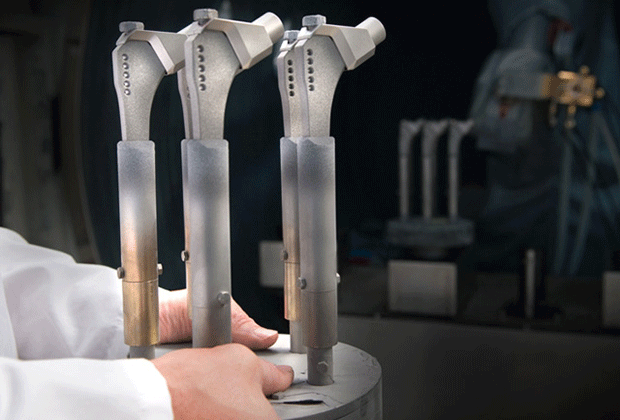

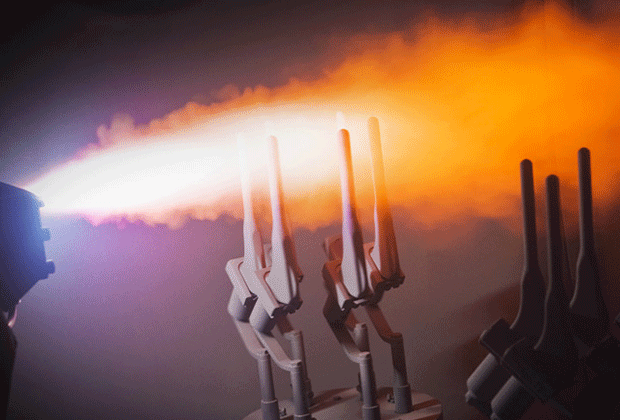

Medicoat is specialist for thermal spray technology with focus on plasma spraying.

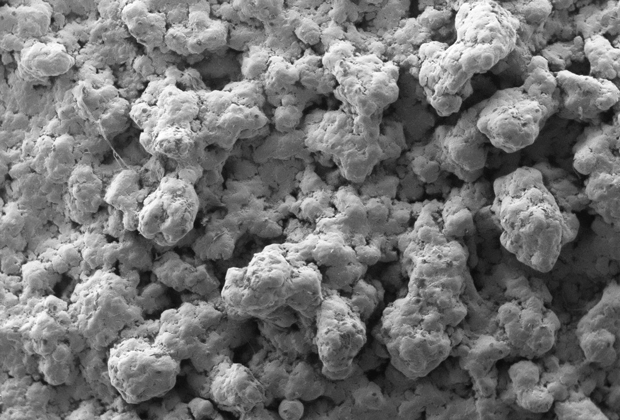

Coatings are realising specific surface properties which can not be performed by the substrate itself.

Through separation of function, different requirements can be fullfilled at the same time. Form and material of the substrate are mainly determined by the mechanical properties. The function in relation to the environment and the load defines the coating and following the coating technology.

It is a combination of surface effects and material factors which needs to be optimized for the specifc application.

Modern surface engineering is chracterized by a variety of coating processes. Medicoat uses properties of different plasma coating processes to apply biocompatible and bioactive coating on implants.